The Complete Guide to Choosing a Custom Gearbox Manufacturer

In today’s industrial automation and advanced engineering sectors, standard gearboxes often struggle to meet the complex demands of specialized applications. That’s where a reliable custom gearbox manufacturer becomes a critical partner. By delivering application-specific gearbox solutions, custom manufacturers help businesses achieve higher efficiency, greater precision, and long-term durability that off-the-shelf products simply cannot match.

Unlike mass-produced units, custom gearboxes are engineered around your exact operating requirements—from torque and speed ratios to space constraints and environmental conditions. This tailored approach ensures seamless system integration, optimized energy transfer, and extended equipment lifespan. Whether powering robotic arms, heavy-duty mixers, conveyors, or highly specialized machinery, custom gearboxes significantly reduce maintenance costs, minimize downtime, and improve overall system reliability.

As industries continue to evolve toward automation, precision control, and energy efficiency, the demand for custom gearbox solutions is no longer optional—it is essential. Choosing the right custom gearbox manufacturer directly impacts productivity, operational stability, and total cost of ownership.

This guide will walk you through the key benefits of custom gearboxes, explain the custom gearbox manufacturing process, and highlight how to select the right manufacturer to support your project goals. Investing in a custom gearbox is more than a technical upgrade—it is a strategic decision that drives innovation, enhances reliability, and delivers measurable long-term cost savings.

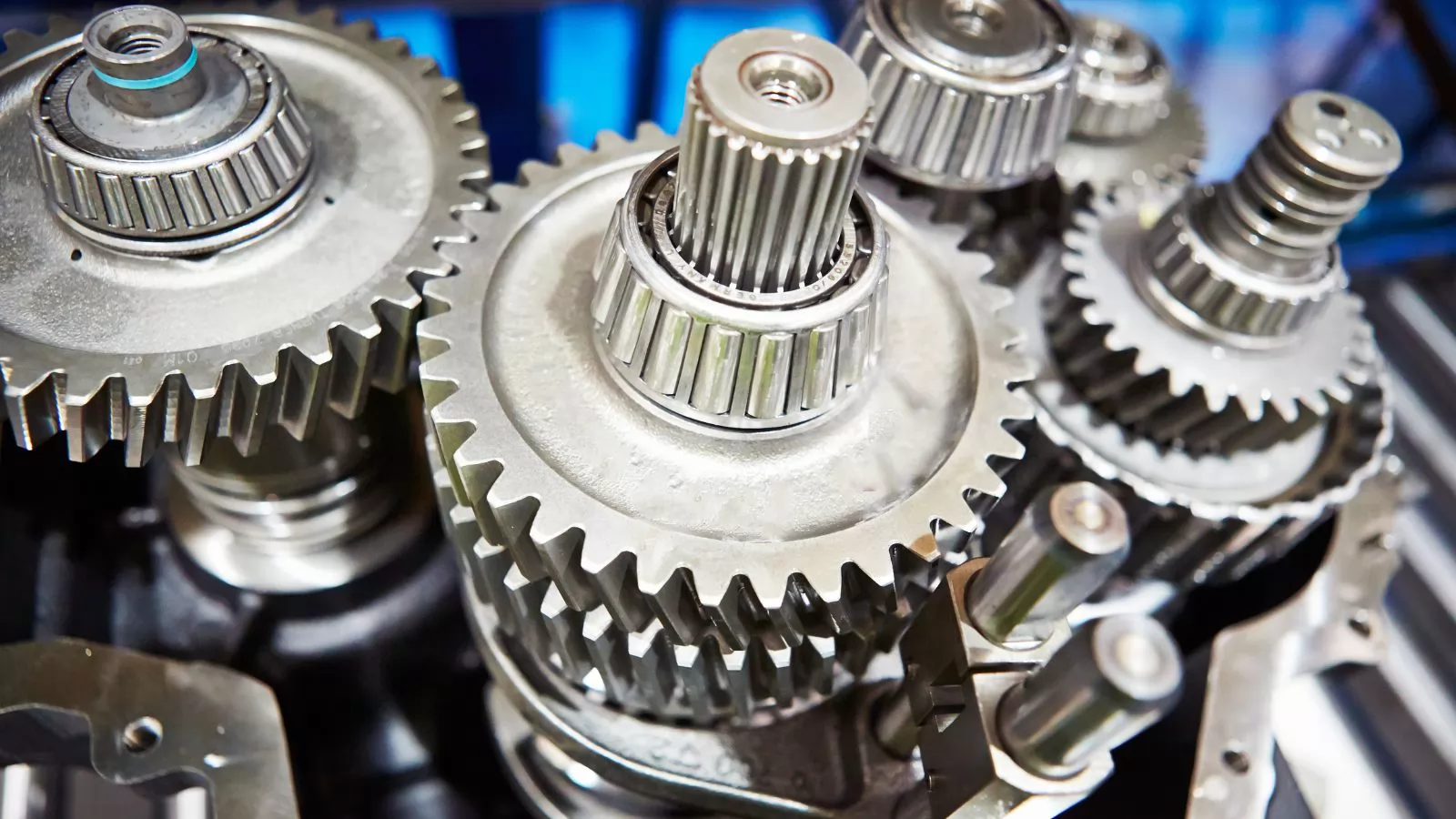

What Exactly is a Custom Gearbox?

A custom gearbox is a precision-engineered mechanical system designed to transmit and regulate rotational power—controlling speed, torque, and direction—to meet the exact needs of a specific application. Unlike standard off-the-shelf gearboxes, custom gearboxes are developed around your operating conditions, space constraints, performance targets, and industry requirements.

A professional custom gearbox manufacturer tailors every critical parameter, including gear ratio, tooth profile, housing material, lubrication system, and mounting configuration, to ensure optimal performance and long-term reliability. This level of customization is essential for applications with variable load cycles, limited installation space, strict noise limits, or demanding thermal conditions.

For example, medical equipment gearboxes require ultra-low backlash and high positional accuracy, while mining and heavy-duty industrial gearboxes demand reinforced structures, high torque output, and exceptional durability. In automation and robotics, compact size and efficiency are equally critical.

Leading custom gearbox manufacturers rely on advanced CAD modeling, Finite Element Analysis (FEA), precision CNC machining, and rigorous testing to validate every design—from material selection to final assembly. This engineering-driven approach ensures each gearbox delivers consistent performance under real-world conditions.

Choosing a custom gearbox is more than selecting a component—it’s about partnering with an experienced custom gearbox manufacturer who can deliver a perfect fit for demanding environments, improve system efficiency, reduce maintenance costs, and extend equipment lifespan. A well-designed custom gearbox is not just a product; it’s a long-term investment in reliability, performance, and operational success.

The Advantages of Custom Gearboxes

Choosing custom gearboxes over standard, off-the-shelf solutions offers far more than basic mechanical compatibility. A professionally designed custom gearbox can dramatically improve system efficiency, reliability, and long-term ROI, making it a strategic investment rather than a simple component purchase. Below are the core advantages that leading manufacturers and industrial buyers consistently prioritize when selecting a custom gearbox manufacturer.

-

Optimized Performance and Higher System Efficiency

One of the most compelling benefits of custom gearboxes is their ability to deliver precisely engineered speed ratios and torque outputs tailored to your exact application requirements. Unlike standard gearboxes, which often operate outside their ideal performance range, a custom gearbox is designed to match the motor, load, and duty cycle perfectly.

This precise alignment minimizes power loss, reduces internal friction and heat buildup, and results in higher overall energy efficiency. In automated production lines, for example, a custom gearbox ensures consistent rotational speed and torque stability—directly improving product quality while lowering energy consumption and operating costs.

-

Enhanced Durability and Extended Service Life

Premature gearbox failure is often caused by mismatched load conditions or improper material selection. A trusted custom gearbox manufacturer designs gearboxes based on your specific load profiles, operating cycles, and environmental conditions.

By selecting optimized gear materials, advanced heat treatments, and appropriate bearing systems, custom gearboxes are built to withstand real-world stresses over extended periods. This results in a longer operational lifespan, reduced unplanned downtime, lower maintenance frequency, and significantly fewer replacement costs—critical factors for continuous industrial operations.

-

Superior Precision and Motion Accuracy

High-precision applications such as robotics, medical equipment, CNC machinery, and advanced automation systems demand minimal backlash and exceptional repeatability. Custom gearboxes can be engineered using precision gear cutting, optimized tooth profiles, and controlled assembly processes to achieve ultra-low or near-zero backlash.

This level of motion accuracy ensures smooth torque transmission, precise positioning, and repeatable performance—capabilities that standard gearbox designs often cannot provide without compromise.

-

Space-Saving and Weight-Optimized Design

Modern equipment designs frequently face strict constraints related to installation space, weight limits, or unique mounting interfaces. Custom gearboxes allow engineers to optimize housing geometry, shaft orientation, and internal layouts to fit seamlessly into compact or unconventional spaces.

This flexibility is especially valuable in industries such as aerospace, automotive systems, mobile machinery, and portable equipment, where reducing size and weight directly enhances performance and efficiency. A custom gearbox integrates cleanly into your system—without forcing design concessions elsewhere.

-

Reduced Noise and Vibration for Smoother Operation

Noise and vibration are more than comfort issues—they can signal inefficiencies, accelerate component wear, and affect system stability. Through optimized gear geometry, precision machining, and balanced assembly, custom gearboxes can significantly reduce operational noise and vibration.

This results in quieter, smoother operation, improved workplace conditions, and enhanced reliability—particularly important for applications involving precision instruments, laboratory equipment, or noise-sensitive environments.

Industries Revolutionized by Bespoke Gearbox Solutions

Across today’s advanced industrial landscape, bespoke gearbox solutions are redefining how power is transmitted, controlled, and optimized. From precision-driven automation to heavy-duty energy systems, custom gearboxes enable industries to overcome unique operational challenges that standard gear units simply cannot address.

By working with an experienced custom gearbox manufacturer, businesses gain tailored performance, higher reliability, and long-term cost efficiency—key drivers for competitiveness and innovation.

-

Robotics & Industrial Automation

In robotics and automation, precision, low backlash, compact design, and repeatability are non-negotiable. Custom gearboxes are engineered to deliver ultra-smooth motion control for robotic arms, collaborative robots (cobots), and automated guided vehicles (AGVs).

These bespoke solutions allow robots to perform delicate assembly, micro-positioning, high-speed pick-and-place, and precision welding tasks with exceptional accuracy. By optimizing torque density and minimizing vibration, custom gearboxes significantly improve system stability, productivity, and uptime in high-speed manufacturing environments.

- Aerospace and Defense

Aerospace and defense applications demand lightweight design, extreme reliability, and flawless performance under harsh conditions such as high temperatures, vibration, and pressure fluctuations.

Custom gearboxes are widely used in aircraft landing gear systems, flap actuators, helicopter transmissions, satellite positioning mechanisms, and military vehicle drivetrains. Every bespoke gearbox must comply with strict aerospace standards and undergo rigorous testing and certification.

For mission-critical systems, partnering with a specialized custom gearbox manufacturer is essential to ensure safety, durability, and compliance.

- Marine and Offshore

Marine and offshore environments expose equipment to corrosion, heavy loads, and continuous operation. Custom gearboxes are purpose-built for ship propulsion systems, deck machinery, winches, cranes, and offshore drilling platforms.

Through material optimization, advanced sealing, and corrosion-resistant coatings, bespoke gearboxes deliver high torque and long service life—even in saltwater and extreme weather conditions.

- Renewable Energy (Wind Turbines)

In wind energy systems, gearboxes play a critical role in converting slow blade rotation into high-speed generator input. These systems operate under constantly varying loads and must endure decades of service in harsh climates.

Custom gearbox designs help optimize efficiency, reduce operational noise, and extend service intervals. As a result, the custom gearbox manufacturer becomes a strategic partner in improving turbine performance, reliability, and overall return on investment in green energy projects.

-

Medical & Pharmaceutical Equipment

Compactness, quiet operation, and extreme precision are vital for medical devices. Custom gearboxes are used in surgical robots, diagnostic equipment, prosthetics, and pharmaceutical dispensing systems. They must meet stringent hygiene standards, operate silently, and deliver precise movements for patient safety and accurate treatment.

- Industrial Machinery and Manufacturing

From packaging lines and conveyors to extruders, mixers, and presses, industrial machinery often demands specific torque, speed ratios, and mounting configurations.

Custom gearboxes provide optimized power transmission solutions that improve throughput, reduce energy consumption, and enhance operational reliability. By tailoring gear geometry and housing design, manufacturers achieve higher efficiency and longer equipment lifespan across diverse production environments.

- Automotive and Motorsports

While mass-market vehicles rely on standard transmissions, high-performance automotive and motorsports applications require custom gearbox solutions engineered for specific power curves, reduced weight, and extreme durability.

Bespoke gearboxes enable faster acceleration, improved handling, and consistent performance under high stress—making them indispensable for racing, specialty vehicles, and advanced drivetrain development.

Choosing the Right Custom Gearbox Manufacturer: A Critical Decision

Choosing the right custom gearbox manufacturer is a critical decision that directly impacts your project’s performance, reliability, and long-term operating costs. An experienced manufacturer does more than produce components — they act as a technical partner throughout the design and production process.

When evaluating a custom gearbox manufacturer, prioritize companies with proven industry experience, strong in-house engineering teams, and advanced manufacturing technologies such as CNC machining and precision gear cutting. Equally important are ISO-certified quality control systems, which ensure consistent performance, traceability, and durability across every gearbox produced.

Expertise in material selection, heat treatment, and metallurgy is essential for achieving optimal torque transmission, wear resistance, and service life — especially in demanding industrial environments. A reliable manufacturer should also offer design flexibility, short lead times, and responsive technical support, enabling faster development and smoother project execution.

A trusted custom gearbox manufacturer delivers tailor-made gearbox solutions engineered to your exact specifications, helping you reduce downtime, extend equipment lifespan, and maximize return on investment.

Key Considerations When Specifying Your Custom Gearbox

When working with a custom gearbox manufacturer, clearly defining your technical and operational requirements is the foundation for achieving optimal performance, long service life, and cost efficiency. The more precise your specifications, the easier it is for manufacturers to design a custom gearbox solution that integrates seamlessly into your system.

-

Input Power, Speed, and Output Torque

Start by specifying the input power, operating speed, and required output torque, as these parameters directly determine the gearbox structure, gear ratio, and internal components. Accurate data ensures the gearbox delivers reliable performance without overengineering or premature wear.

-

Operating Environment & Protection Requirements

Environmental conditions significantly affect custom gearbox design. Clearly communicate factors such as:

-

Operating temperature range

-

Exposure to moisture, dust, chemicals, or corrosive elements

These details guide material selection, surface treatments, and sealing solutions to enhance durability in demanding environments.

-

Space Constraints & Mounting Configuration

Provide exact dimensional limits, mounting orientation, shaft type, and connection interfaces. Custom gearboxes are often designed for tight spaces or unique layouts, so precise spatial data ensures perfect fit and smooth system integration.

-

Duty Cycle, Service Life & Noise Limits

Define your gearbox’s duty cycle, expected lifespan, and noise or vibration limits. Whether the application involves intermittent loads or continuous operation, these factors influence gear geometry, bearing selection, and housing design to maintain long-term reliability.

-

Lubrication & Thermal Management

Lubrication methods and cooling requirements are critical, especially for high-torque or continuous-duty custom gearboxes. Inform your manufacturer if the application requires:

-

Special lubricants

-

Oil circulation systems

-

Additional cooling solutions

Proper thermal management prevents overheating and extends gearbox life.

-

Budget, Lead Time & Scalability

Set clear expectations regarding budget range, target lead time, and future production volume. Early alignment helps the custom gearbox manufacturer optimize design, sourcing, and production schedules while controlling overall project costs.

-

Standards, Certifications & Compliance

Ensure the gearbox complies with relevant industry standards and certifications, such as AGMA, CE, UL, or ISO, depending on your market and application. Compliance not only improves safety and quality but also simplifies global deployment.

The Future of Custom Gearbox Manufacturing: Smart, Efficient, and Sustainable

The custom gearbox manufacturing industry is undergoing a rapid transformation driven by advanced materials, additive manufacturing, and intelligent technologies. Leading custom gearbox manufacturers are increasingly adopting lightweight yet durable materials, along with 3D printing techniques, to produce complex gearbox structures that deliver higher efficiency, improved strength, and reduced weight.

One of the most significant advancements is the rise of smart gearboxes. By integrating IoT sensors and digital monitoring systems, modern custom gearboxes enable real-time performance tracking, predictive maintenance, and early fault detection. This not only minimizes unexpected downtime but also extends service life and lowers total operating costs for industrial users.

At the design stage, AI and machine learning technologies are reshaping how custom gearbox solutions are developed. By analyzing large volumes of performance and load data, manufacturers can optimize gear geometry, material selection, and efficiency before production begins—resulting in highly reliable and cost-effective gearbox designs tailored to specific applications.

Sustainability is also becoming a key focus in custom gearbox manufacturing. Eco-friendly processes, material optimization, energy-efficient production methods, and waste reduction initiatives are helping manufacturers meet global environmental standards while maintaining high performance and durability.

With these innovations, forward-thinking custom gearbox manufacturers are able to deliver intelligent, high-performance, and environmentally responsible gearbox solutions—perfectly suited for demanding industrial, automation, and precision engineering applications.

Conclusion

Choosing the right custom gearbox manufacturer is more than a purchase — it’s a strategic decision that directly impacts your machinery’s efficiency, reliability, and long-term performance. Unlike standard gearboxes, custom gearbox solutions are tailored to meet the exact requirements of robotics, renewable energy systems, heavy machinery, and other industrial applications.

With a high-quality custom gearbox, you can enjoy:

-

Optimized Performance: Gear ratios, torque, and speed perfectly matched to your machine’s needs.

-

Extended Lifespan: Durable materials and precision engineering reduce wear and maintenance frequency.

-

Reduced Operational Costs: Fewer breakdowns and downtime improve overall productivity.

Partnering with a trusted custom gearbox manufacturer also gives you access to advanced engineering expertise, tailored support, and innovative solutions designed specifically for your industrial challenges.

Invest in precision engineering that drives your success. Contact us today to discuss your specifications and discover how a custom gearbox can unlock your machinery’s full potential.

-

Aug 22, 2025How Does a Brushless Electric Motor Work? A Beginner's Guide

Aug 22, 2025How Does a Brushless Electric Motor Work? A Beginner's Guide -

Sep 16, 2025Top 10 DC Motor Manufacturers in China 2025

Sep 16, 2025Top 10 DC Motor Manufacturers in China 2025 -

Aug 21, 2025Which Motor Is Best for Electric Vehicle? A Complete Guide for 2025

Aug 21, 2025Which Motor Is Best for Electric Vehicle? A Complete Guide for 2025 -

Sep 05, 2025Top 10 Gear Motor Manufacturers in India 2025

Sep 05, 2025Top 10 Gear Motor Manufacturers in India 2025