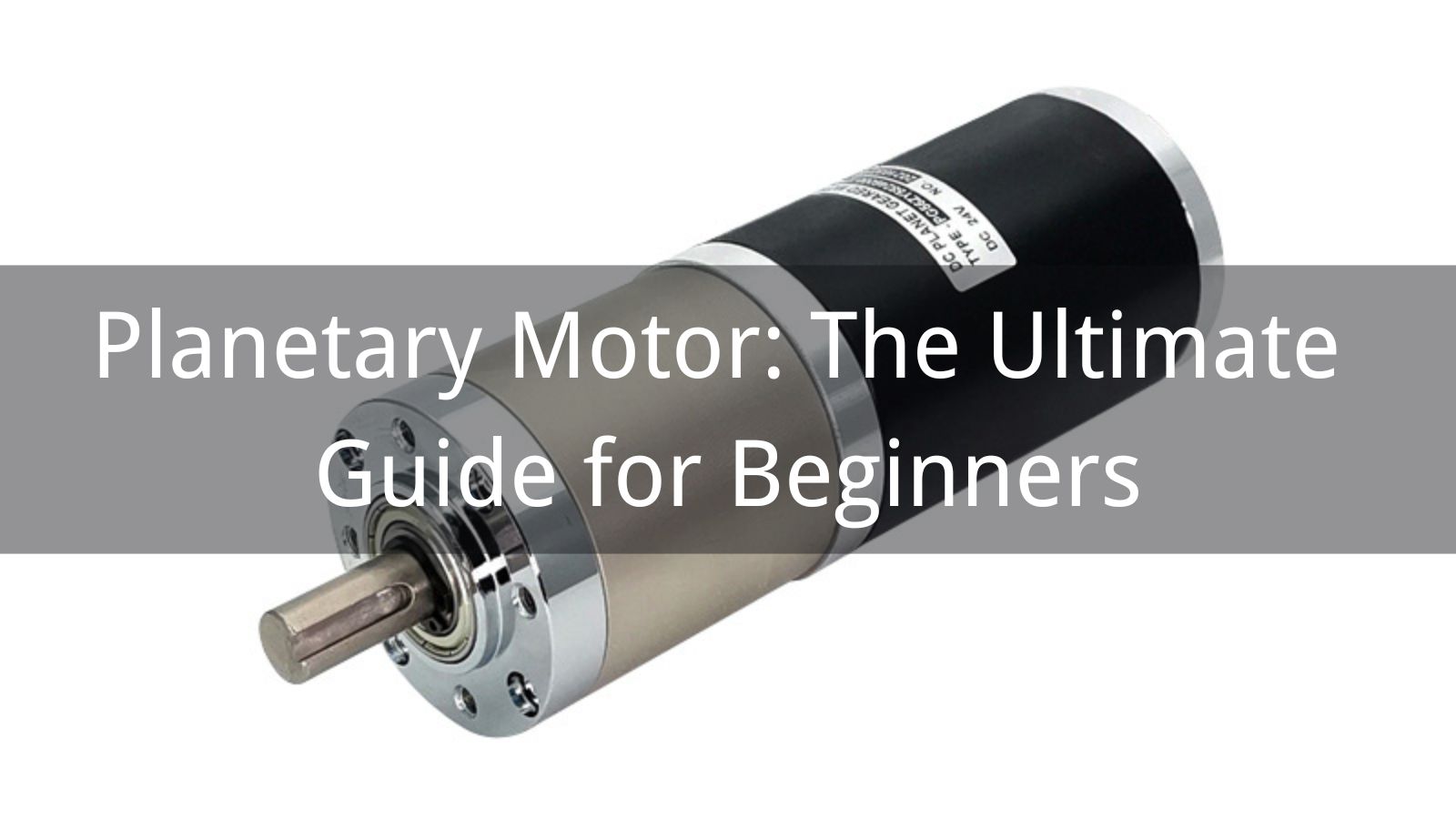

High Torque Gear Motor: Ultimate Guide for Industrial Applications

High torque gear motors play a critical role in today's industrial applications, where reliable power and efficiency are non-negotiable. By combining a motor with a gearbox, these systems deliver high torque at low speeds, making them ideal for heavy-duty operations such as conveyor systems, automated robotics, packaging machinery, and lifting equipment. Compared with standard motors, a high torque gear motor ensures greater load capacity, improved precision, and long-term durability, even in harsh environments.

For manufacturers and engineers, choosing the right high torque gear motor not only boosts productivity but also reduces maintenance costs and downtime. This guide will explore what makes these motors essential, the types available, and how to select the best option for your specific industrial needs.

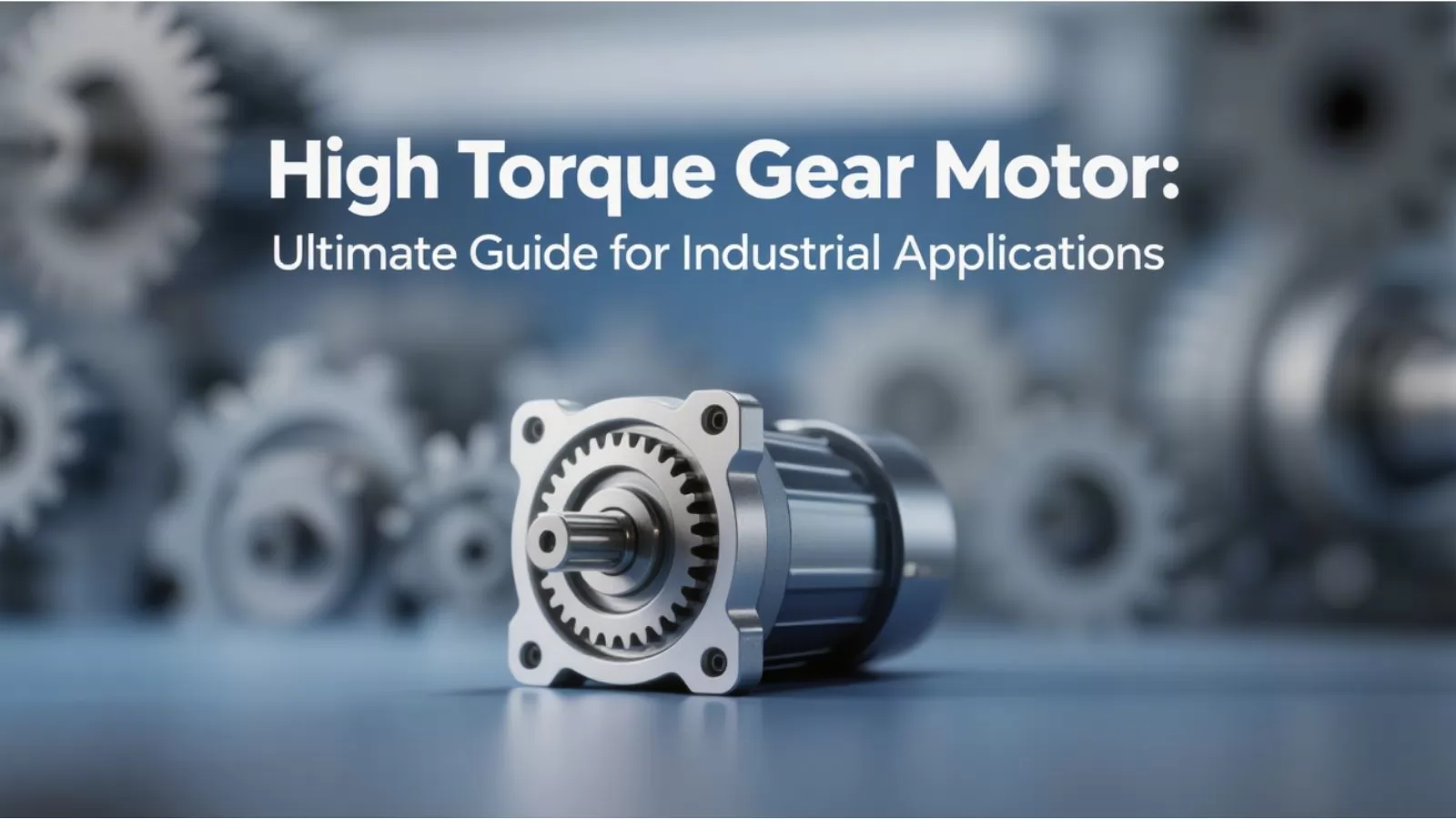

What is a High Torque Gear Motor?

A high torque gear motor is engineered to deliver powerful rotational force at low speeds, making it essential for heavy-duty industrial applications. By integrating a gearbox with a high-torque output, these motors ensure reliable performance in demanding tasks such as lifting, conveying, robotics, and automated machinery.

Their ability to handle substantial loads while maintaining precision, durability, and energy efficiency makes high torque gear motors a preferred choice in modern manufacturing. Whether for conveyor systems, automation, or robotics, selecting the right high torque gear motor is key to maximizing productivity and long-term reliability.

Key Features of High Torque Gear Motor

High torque gear motors combine compact size, high torque density, and energy-efficient performance, making them indispensable in industrial applications. These motors handle heavy loads with minimal speed loss, ensuring reliable operation in robotics, conveyors, and lifting systems. With planetary, spur, and helical gear configurations, they provide precise torque control, low noise, and long service life.

Their robust design and durability guarantee consistent performance even in demanding environments. When choosing a high torque gear motor, engineers should evaluate speed, torque capacity, and load type to achieve optimal system efficiency and seamless integration.

Applications of High Torque Gear Motors in Industry

High torque gear motors are widely used in various industrial applications that require reliable power and precision. These motors are essential in conveyor systems, where they efficiently handle heavy loads and continuous operation. In automated machinery, high torque gear motors provide the necessary force for accurate, repetitive movements. They are also commonly used in robotics, enabling precise positioning and smooth motion control. Industries such as automotive manufacturing, aerospace, and material handling rely on high torque gear motors for lifting, rotating, and driving large components.

Their compact design and ability to deliver high output torque in limited spaces make them ideal for complex systems. By integrating high torque gear motors in industrial applications, companies can improve efficiency, reduce downtime, and ensure consistent performance under demanding conditions. Choosing the right high torque gear motor tailored to your specific application is key to achieving long-term success and operational reliability.

Leading High Torque Gear Motor Manufacturers

Choosing the right high torque gear motor manufacturer is crucial for ensuring performance and reliability in industrial applications. Leading suppliers like Toosyn deliver high-quality, durable gear motors backed by industry certifications and advanced customization options.

When evaluating a reliable supplier, consider product quality, technical expertise, global service support, and competitive pricing. Partnering with reputable gear motor manufacturers such as Toosyn guarantees efficient operation, reduced downtime, and long-term value for your business.

How to Choose the Right High Torque Gear Motor

- Determine Your Torque and Load Requirements

When selecting a high torque gear motor, always calculate torque, load, and speed requirements accurately. Both starting and running torque must match your machinery to avoid overload. A well-matched gear motor enhances efficiency, reduces wear, and ensures consistent performance in industrial applications. Accurate load assessment directly improves productivity and long-term durability.

- Evaluate Motor Size and Space Constraints

Choose a high torque gear motor that fits your equipment layout without compromising torque capacity. Compact and space-saving designs are crucial in modern automation systems. Properly sizing the motor prevents installation challenges, improves machine integration, and ensures smooth operation. A well-fitted gear motor boosts productivity while maintaining system stability and energy efficiency.

- Consider Environmental Conditions

Operating conditions significantly impact high torque gear motor performance. Factors like dust, moisture, vibration, or chemical exposure demand motors with strong IP protection ratings. Choosing a motor designed for harsh environments extends service life, reduces downtime, and improves safety. The right gear motor ensures reliable performance in demanding industrial applications.

- Check Duty Cycle and Operating Hours

Different high torque gear motors are designed for continuous duty or intermittent operation. Matching duty cycle to workload prevents overheating, energy loss, and premature motor failure. For heavy-duty systems, choose a motor capable of long operating hours without efficiency loss. Aligning motor duty rating with actual usage ensures stable, cost-effective performance.

- Focus on Energy Efficiency and Performance

An efficient high torque gear motor lowers long-term operating costs while maintaining torque output. Look for motors with high efficiency ratings that reduce energy waste and optimize performance. Energy-efficient gear motors contribute to sustainability goals, extend system life, and improve industrial productivity. This balance of power and efficiency ensures maximum return on investment.

- Assess Customization Options and Flexibility

Some applications need a custom high torque gear motor with unique shafts, mounting, or gear ratios. Manufacturers offering tailored solutions allow precise adaptation to specific systems. A customizable motor ensures better compatibility, efficiency, and long-term reliability. Investing in flexible gear motor solutions maximizes industrial performance and avoids costly design compromises.

- Verify Manufacturer Reliability and After-Sales Support

Partnering with a reputable high torque gear motor manufacturer ensures consistent quality and dependable after-sales service. Check certifications, client reviews, and warranty policies before purchasing. A reliable supplier provides durable gear motors, technical guidance, and spare parts availability. Strong manufacturer support safeguards your investment and enhances system uptime in industrial operations.

Maintenance Tips for High Torque Gear Motors

- Regular Lubrication to Ensure Smooth Operation

Regular lubrication is essential for every high torque gear motor. Using the manufacturer-recommended lubricants reduces friction, prevents gear wear, and ensures smooth operation under heavy loads. A proper lubrication schedule also extends the motor’s service life and keeps performance consistent, especially in demanding industrial applications.

- Monitor Gear Motor Temperature During Operation

Monitoring temperature is critical for maintaining high torque gear motors. Overheating often signals overloading, poor ventilation, or inadequate lubrication. By keeping the operating temperature within the safe range, you protect the motor from thermal stress, improve reliability, and ensure long-term efficiency in heavy-duty machinery.

- Inspect for Abnormal Noise and Vibrations

Noise and vibration are early warning signs of issues in high torque gear motors. Regular inspections can detect misalignment, gear wear, or internal faults. Addressing these problems promptly prevents costly downtime, extends the lifespan of gears and bearings, and maintains stable performance in industrial operations.

- Perform Routine Visual Inspections for Leaks and Wear

Routine inspections help keep a high torque gear motor in peak condition. Look for oil leaks, worn seals, loose bolts, or cracked components. Identifying these issues early allows for timely maintenance, ensuring smooth operation and avoiding unexpected failures in demanding industrial environments.

- Check Electrical Connections and Motor Mounting

Electrical safety and proper installation are vital for high torque gear motors. Inspect connections for corrosion, loose wiring, or damage, and ensure the motor is securely mounted. Proper alignment reduces vibration, mechanical stress, and electrical risks, ensuring stable operation and extending the gear motor’s lifespan.

Conclusion: Why High Torque Gear Motors Are Essential for Your Industry

High torque gear motors are essential for industrial applications, providing powerful torque, efficiency, and long-term reliability. From automation and manufacturing to robotics and conveyor systems, these gear motor solutions ensure consistent performance, reduce downtime, and optimize costs. Their durability, energy efficiency, and customizable options make them the ideal choice for demanding operations.

Maximize your productivity with Toosyn's high torque gear motors—contact us today to explore tailored solutions for your industry!

Related Pages

-

Aug 22, 2025How Does a Brushless Electric Motor Work? A Beginner's Guide

Aug 22, 2025How Does a Brushless Electric Motor Work? A Beginner's Guide -

Sep 16, 2025Top 10 DC Motor Manufacturers in China 2025

Sep 16, 2025Top 10 DC Motor Manufacturers in China 2025 -

Aug 21, 2025Which Motor Is Best for Electric Vehicle? A Complete Guide for 2025

Aug 21, 2025Which Motor Is Best for Electric Vehicle? A Complete Guide for 2025 -

Sep 05, 2025Top 10 Gear Motor Manufacturers in India 2025

Sep 05, 2025Top 10 Gear Motor Manufacturers in India 2025