PG56ZY58 series 56mm planetary gear motor with encoder and brake(30~100Watt)

Specifications

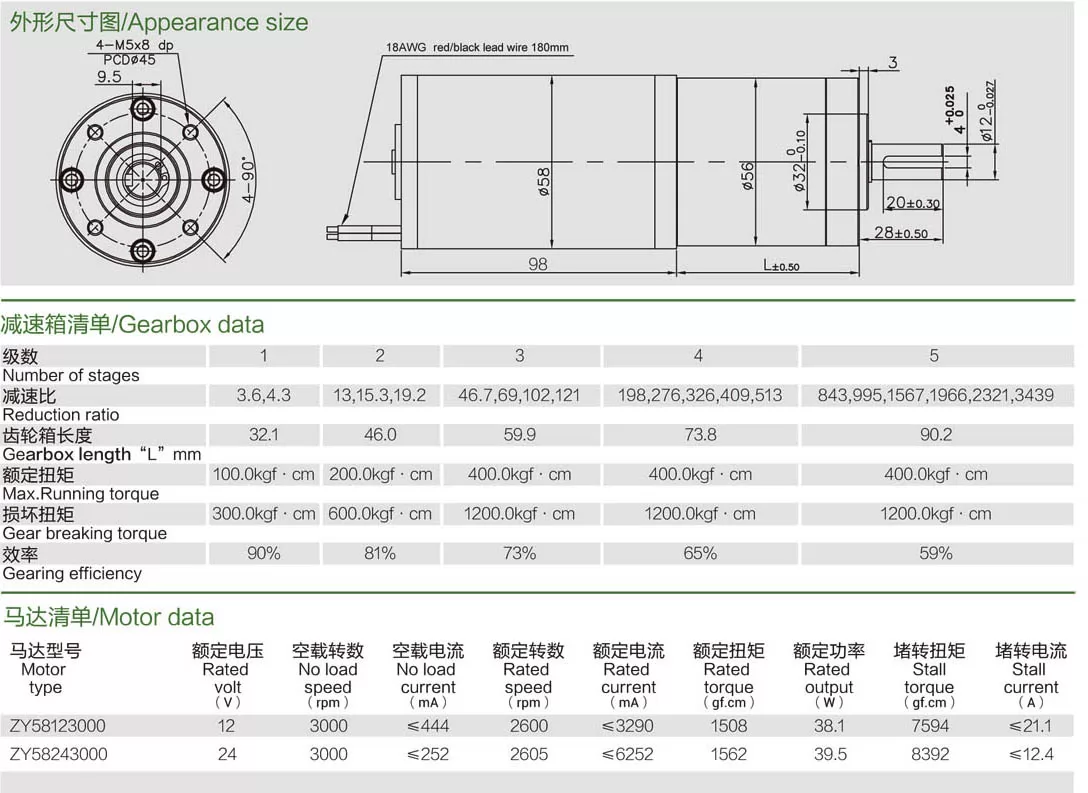

| Parameter | Value |

|---|---|

| Series | PG56ZY58 |

| Diameter | 56mm |

| Motor type | DC brushed motor |

| Gearbox type | Planetary |

| Nominal Voltage | 12VDC,24VDC |

| Rated power | 30-100Watt |

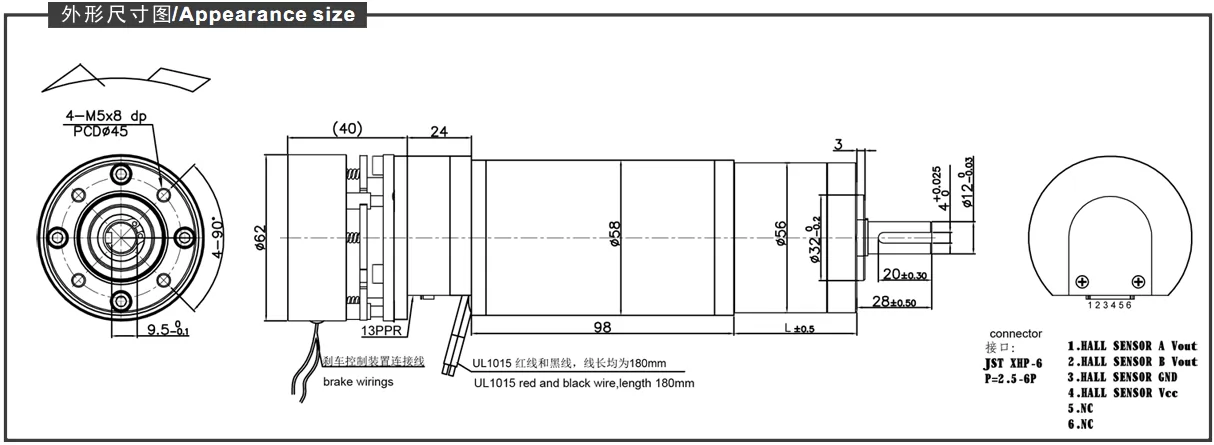

PG56ZY58 series Gearmotor consists of 56mm planetary gearbox ,ZY58 series brushed motor,encoder and brake . The gearmotor can be customized for different speed and torque to meet application requirement, with high durability, high performance.