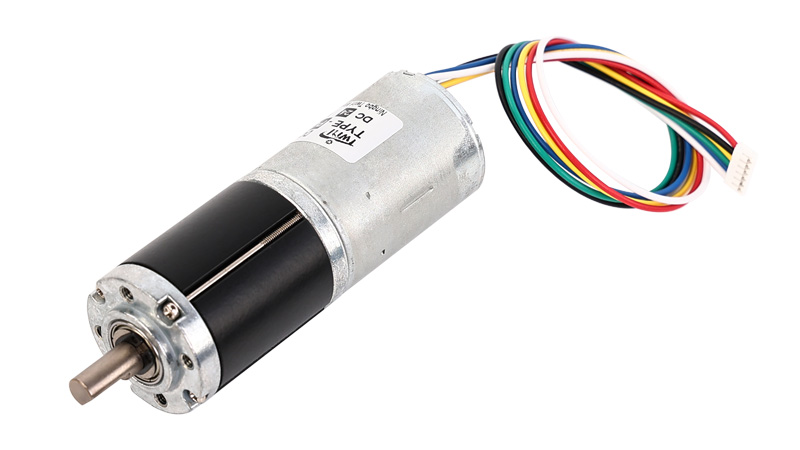

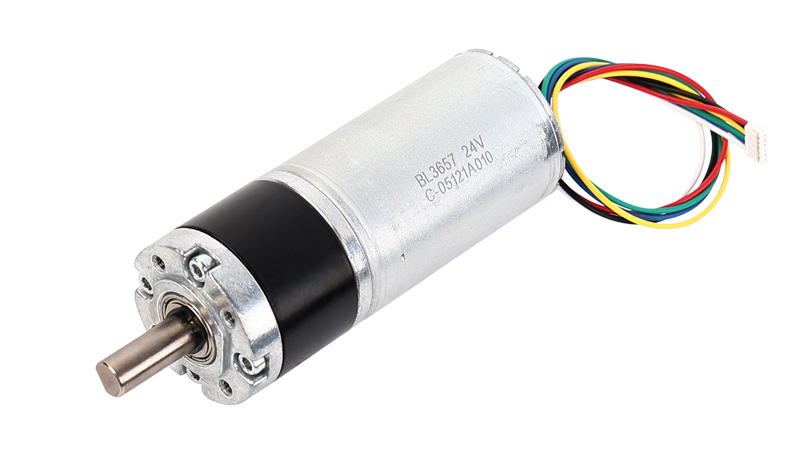

28mm Brushless DC Gear Motor

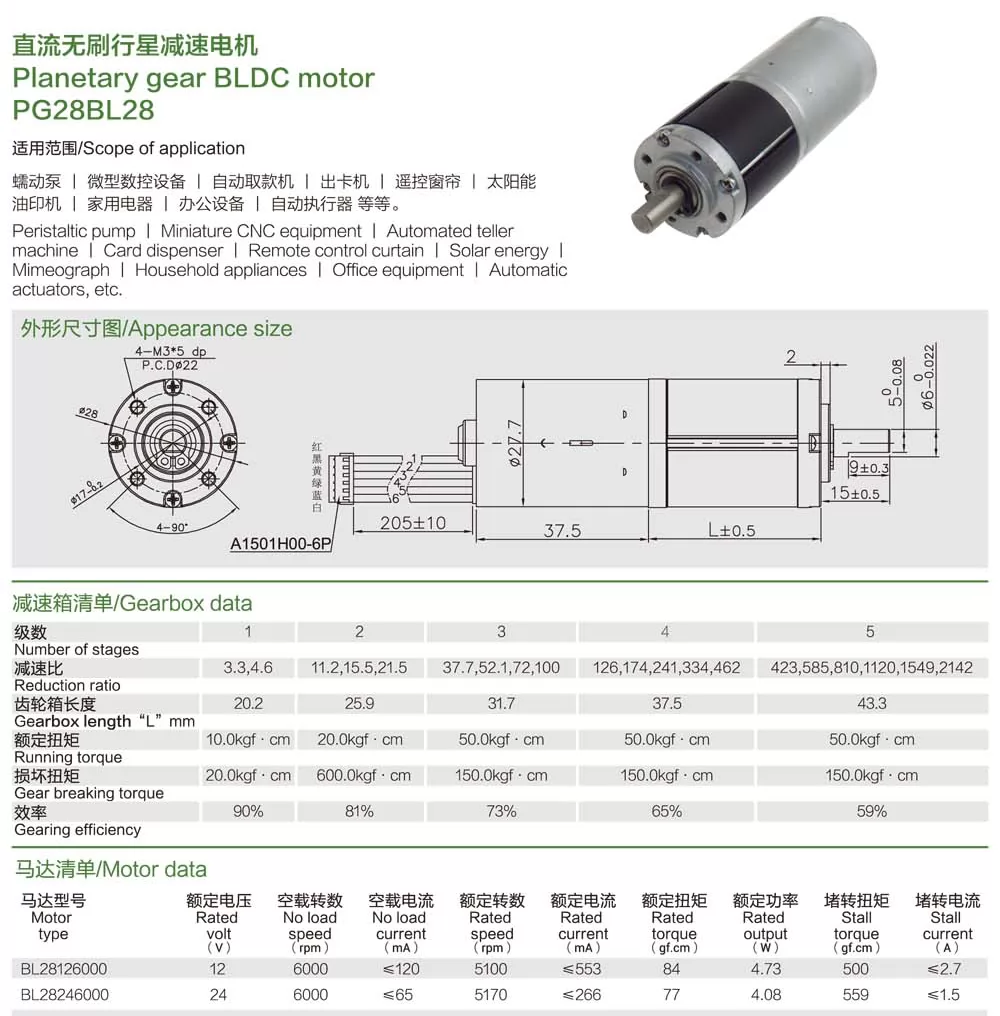

Specifications

| Parameter | Value |

|---|---|

| Series | PG28BL28 |

| Diameter | 28mm |

| Size | 28×(57.7~80.8)mm |

| Motor type | BLDC Gear Motor |

| Rated torque | 10kg.cm~50kg.cm |

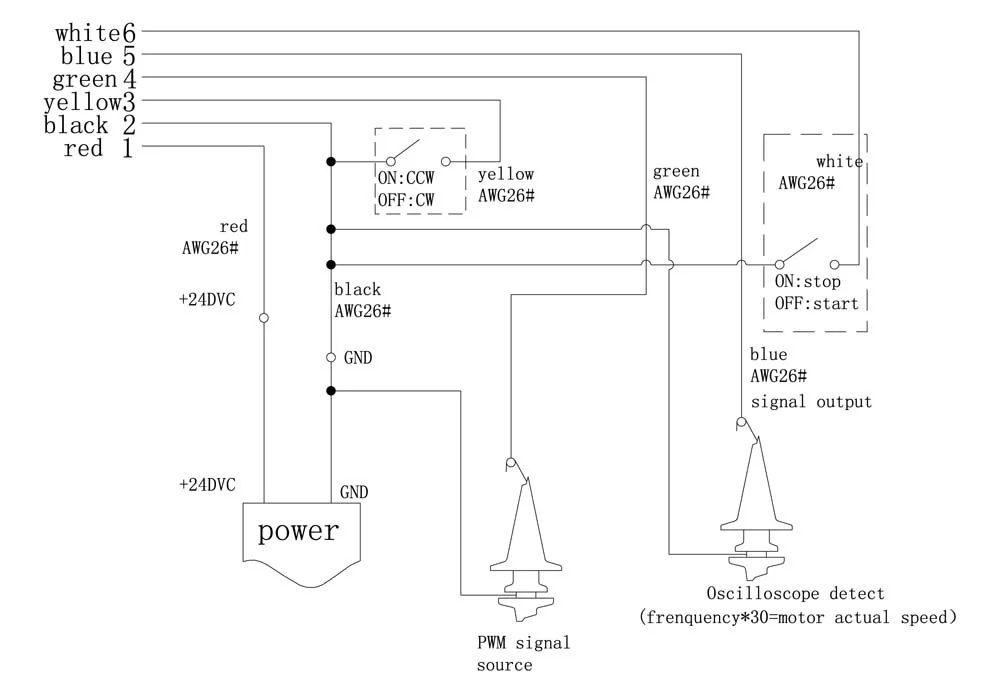

The 28mm Brushless DC Gear Motor offers high efficiency, low noise, and compact design. With robust torque and precise speed control, it’s ideal for robotics, automation, and medical devices. Its durable construction ensures reliable performance in demanding applications.