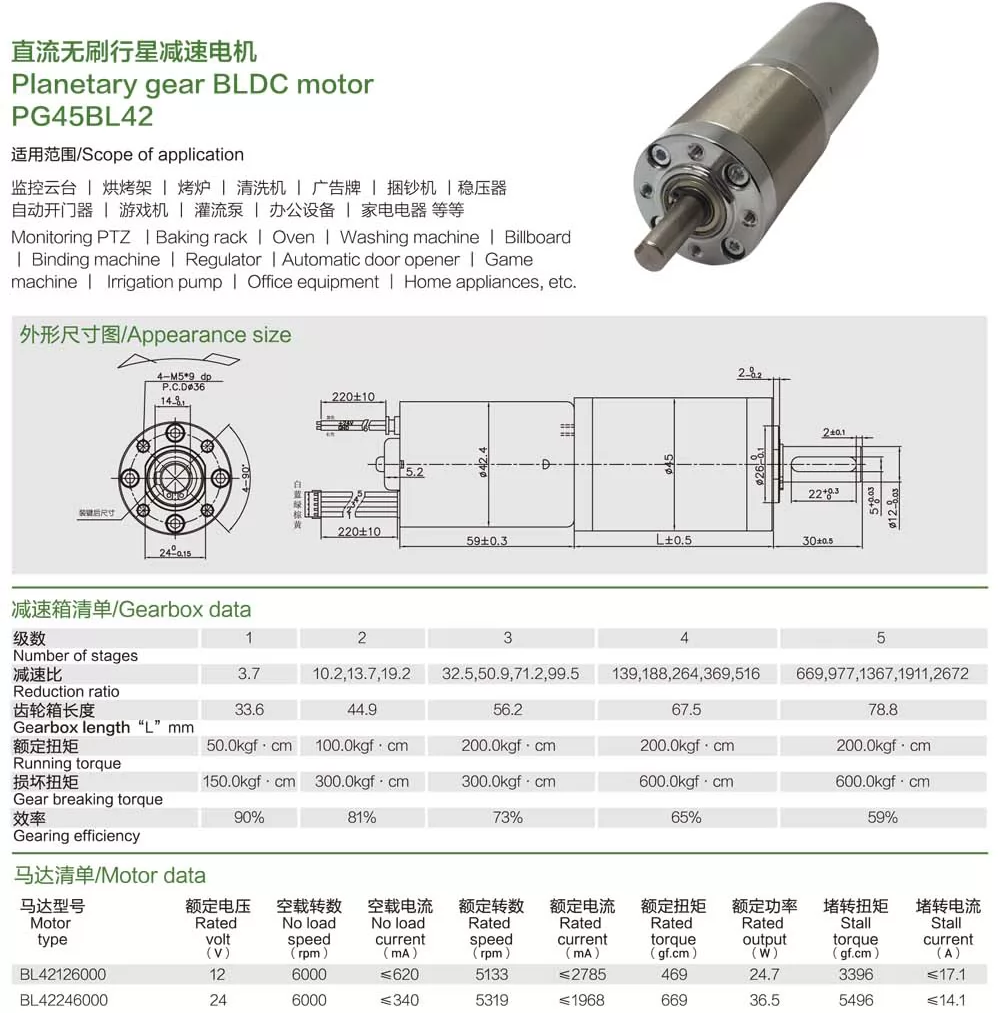

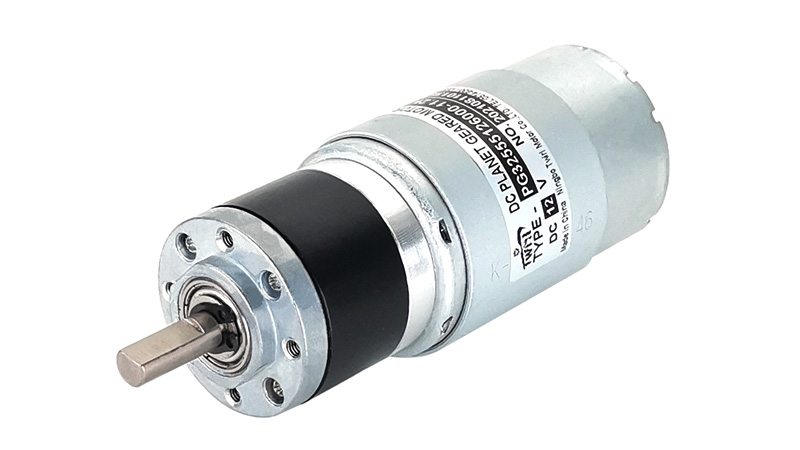

42mm BLDC Gear Motor

Specifications

| Parameter | Value |

|---|---|

| Series | PG42BL42 |

| Diameter | 42mm |

| Gear type | Metal Planetary Gearheadmm |

| Motor type | BLDC Gear Motor |

| Voltage | 12VDC,24VDC,36VDC |

The 42mm BLDC Gear Motor combines high torque, precision control, and compact design. With a long lifespan, low maintenance, and customizable options, it’s ideal for reliable, high-performance industrial applications.